Aluminium Oxide Applied to Ceramic Product

Fine Ceramics, Advanced Ceramics, Alumina Ceramics, Al₂O₃

The precision ceramic parts produced by TOUCH-DOWN Technology can be made of high-purity ceramic raw materials, 92~97% alumina, 99.5% alumina, 99.9% alumina, and CIP cold isostatic pressing. High temperature sintering and precision machining, dimensional accuracy of ± 0.001mm, smoothness up to Ra0.1, use temperature up to 1600 degrees. Different colors of ceramics can be made according to customers' requirements, such as: black, white, beige, dark red, etc. The precision ceramic parts produced by our company are resistant to high temperature, corrosion, wear and insulation, and can be used for a long time in high temperature, vacuum and corrosive gas environment.

Widely used in a variety of semiconductor production equipment: Frames (ceramic bracket), Dome (cover), Substrate (base), Arm (manipulator), Tray, Roller , Small Part , Bolt (Threaded teeth), Screws and other products above.

Application Of High Purity Alumina Ceramics

1. Applied to semiconductor equipment: ceramic vacuum chuck, cutting disc, cleaning disc, ceramic CHUCK

2. Wafer transfer parts: wafer handling chucks, wafer cutting discs, wafer cleaning discs, wafer optical inspection suction cups

3. LED / LCD flat panel display industry: ceramic nozzle, ceramic grinding disc, LIFT PIN, PIN rail

4. Optical communication, solar industry: ceramic tubes, ceramic rods, circuit board screen printing ceramic scrapers

5. Heat-resistant and electrically insulating parts: ceramic bearings

At present, aluminum oxide ceramics can be divided into high purity and common ceramics. The high purity aluminum oxide ceramics series refers to the ceramic material containing more than 99.9% Al₂O₃. Because of its sintering temperature of up to 1650 - 1990°C and its transmission wavelength of 1 ~ 6μm, it is usually processed into fused glass instead of platinum crucible: which can be used as sodium tube owing to its light transmittance and corrosion resistance to alkali metal. In the electronics industry, it can be used as the high-frequency insulating material for IC substrates. According to different contents of aluminum oxide, the common aluminum oxide ceramic series can be divided into 99 ceramics, 95 ceramics, 90 ceramics and 85 ceramics. Sometimes, the ceramics with 80% or 75% of aluminum oxide is also classified as common aluminum oxide ceramic series. Among them, 99 aluminum oxide ceramic material is used to produce high-temperature crucible, fireproofing furnace tube and special wear-resistant materials, such as ceramic bearings, ceramic seals and valve plates. 95 aluminum ceramics is mainly used as corrosion-resistant wear-resisting part. 85 ceramics is often mixed in some properties, thereby improving electrical performance and mechanical strength. It can use molybdenum, niobium, tantalum and other metal seals, and some are used as electric vacuum devices.

| Quality Item (Representative Value) | Product Name | AES-12 | AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

|---|---|---|---|---|---|---|---|---|---|

| Chemical Composition Low-Sodium Easy Sintering Product | H₂O | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| L.O.l | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂0₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂0₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

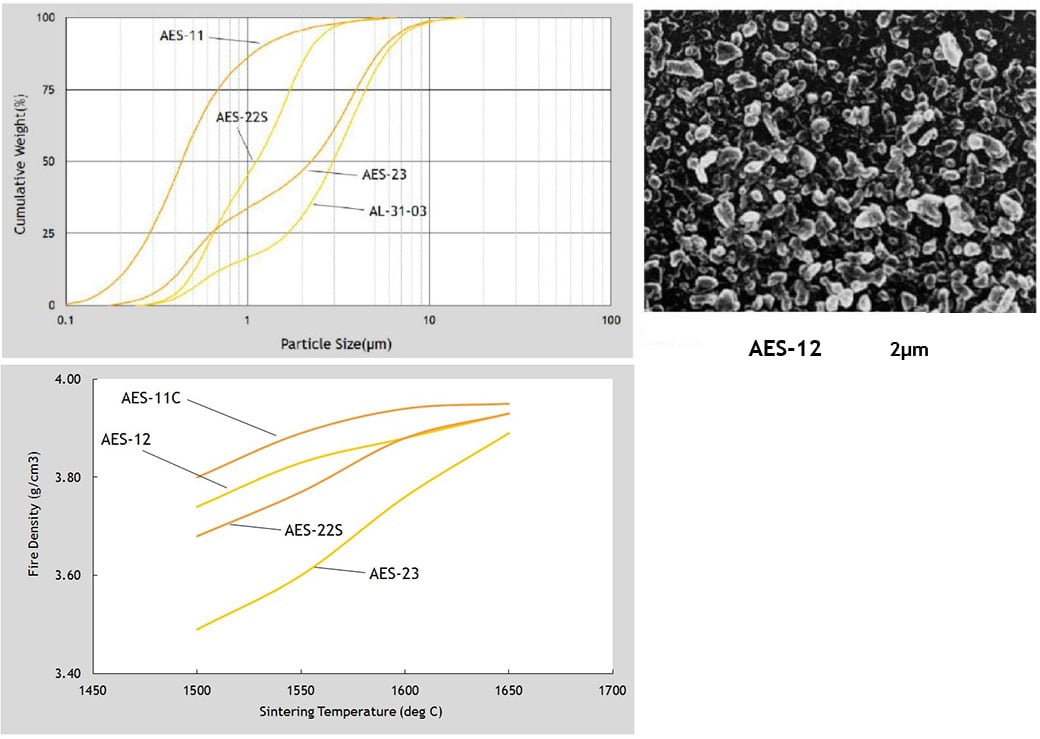

| Medium Particle Diameter (MT-3300, laser analysis method) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3.0 | |

| α Crystal Size | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3 ~ 4 | 0.3 ~ 4 | |

| Forming Density** | g/cm³ | 2.22 | 2.22 | 2.20 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Sintering Density** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Shrinking Rate of Sintering Line** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

*MgO is not included in the calculation of purity of Al₂O₃.

*No scaling powder 29.4MPa (300kg/cm²), sintering temperature is 1600°C.

AES-11 / 11C / 11F: Add 0.05 ~ 0.1% MgO, the sinterability is excellent, so it is applicable to aluminum oxide ceramics with the purity of more than 99%.

AES-22S: Characterized by high forming density and low shrinking rate of sintering line, it is applicable to slip form casting and other large-scale products with required dimensional accuracy.

AES-23 / AES-31-03: It has a higher forming density, thixotropy and a lower viscosity than AES-22S. the former is used to ceramics while the latter is used as water reducer for fireproofing materials, gaining popularity.

- Related Products

-

Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut

Touch-Down (CNC precision machine grinding finished products) ensures the bolt size accuracy. Touch-Down features a complete production line from raw materials...

Details