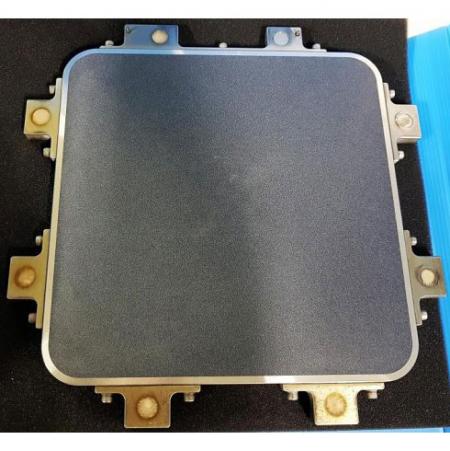

Porous Ceramic Chuck Table, Precise Porous Ceramic Partial Vacuum Chuck

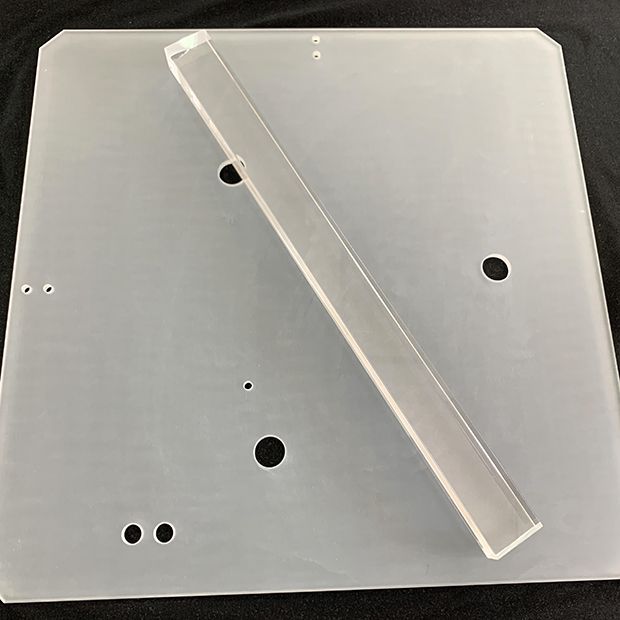

High-density ceramic vacuum chuck (porous ceramic vacuum chuck) features the special porous ceramic material pore size of 2 to 3 microns, which is difficult to block with large vacuum force and part area adsorption. It can also serve as air flotation platform, widely used in semiconductor, panel, laser process and non-contact linear slide. Porous ceramic vacuum chuck maintains transmission through hermetically sealed air. The device application is limited to work platforms for flat, non-porous surfaces. The user is usually a machine operator. In the field of metalworking, this is a safe and reliable transfer of workpiece.

The worktable of automated transfer, object drawing, positioning, precision screen printing leverages on the porous permeable ceramic (alumina or silicon carbide) connected to the vacuum suction to place the workpiece (including wafer, glass, PET film or other thin objects) on the ceramic chuck and use vacuum suction to fix the work piece for cleaning, cutting, grinding, screen printing and other processing procedures.

Ceramic Cutting / Grinding Disc (For Semiconductor)

Wafer clamping system not only includes the role of wafer processing in the process of movement, but also puts working load required for processing on the wafer and ensures that the wafer under the action of the load will not be subject to warping deformation. Therefore, the performance of the wafer clamping system is of great importance to improving the quality of the final wafer product. In response to this demand, the most widely used method in the wafer clamping system at present is to use the vacuum negative pressure to "suck" the "vacuum chuck" of the workpiece, which has the advantages of high efficiency, no pollution, high positioning accuracy and high-hardness abrasion performance and low coefficient of thermal expansion.

Processing Object

Ceramic Vacuum Chuck (Porous Ceramic Vacuum Chuck).

Type

Alumina Ceramic Chuck.

Main Features

Touch-Down boasts a group of excellent engineers and enjoys a unique high-profile technology in the special-shaped ceramic processing projects. Special-shaped processing technology is the strengths of Touch-Down.

Touch-Down produced precision ceramic parts feature good structural strength, high temperature resistance, high pressure resistance, good accuracy, good parallelism, high density and uniform organization. For many years, it has been used by the semiconductor manufacturing plant.

Located near the Science Park of Taiwan Hsinchu, the world-renowned science and technology town, our plant enjoys more than 25 years of professional production and processing experience in alumina, zirconia, silicon nitride, silicon carbide ceramic production and processing. We boast strong technical force, refined equipment and rich processing experience. Now we have several precision CNC equipment, precision machine tools, and a variety of leading processing technology and processing tools as well as sophisticated detection equipment to ensure product quality and precision. We are able to produce precision ceramic parts of a variety of specifications, types according to customer drawings. Our products feature high precision, good performance and are widely used in semiconductor, photovoltaic, precision machinery, military, medical, scientific research and other field.

The Main Products

Ceramic Bolt, Ceramic Shaft, Zirconia Ceramic, Plug Gauge, Ring Gauge, Alumina Ceramic Arm, Ceramic Disc, Ceramic Ring, Microporous Ceramic Vacuum Chuck, Substrate, Ceramic, Ceramic Rails, Special-Shaped Pieces and so on.

Specification

Product Name: Porous Ceramic Vacuum Chuck

Dimensions: 200mm - 500mm x 30mm

Attributes:

Main Components: Alumina

Color: Black / Brown

Alumina Content: 92%

Moisture Content: 0%

Pore Size: 2 ~ 3um

Porosity: 35 ~ 40%

Flexural Strength: 6 kgf / cm² (Mpa)

Volume Ratio: 2.28 g / cm³

- Files Download

-

Precision Ceramics

Touch-Down - Most accurate and professional long-term partner. Welcome to trial and proofing.

Download

Porous Ceramic Chuck Table, Precise Porous Ceramic Partial Vacuum Chuck | Over 30 Years Advanced Ceramic Parts & Components Manufacturer | Touch-Down Technology Co., Ltd

Based in Taiwan since 1997, Touch-Down has been a fine ceramic parts and components manufacturer. Their main ceremic products, including Porous Ceramic Chuck Table, Precise Porous Ceramic Partial Vacuum Chuck, fine ceramics, advanced ceramics and special ceramics integrating production, which are ISO 9001 certified.

Touch-Down is a compact, high-precision ceramic part manufacturer, who is specialized in the manufacture of fine ceramics / advanced ceramics / special ceramics integrating production and sales from raw material preparation, molding, plane grinding, abrasive machining of inner and outer diameters to digital processing of NC drilling crew. Over the past two decades, it has provided products and services for parts manufacturing and processing of fine ceramics, aluminium oxide, zirconium oxide, quartz and silicon carbide in terms of semiconductor processing, LED processing, TFT / LCD processing, solar chip processing, machinery production, medical and pharmaceutical industry and national defense and military.

Touch-Down has been selling advanced ceramics to US, Europe and Australia for over two decades since 1997, both with advanced technology and 30 years of experience, Touch-Down ensures each customer's demands are met.