Precision Ceramic Parts of Semiconductor Process Equipment

Touch-Down boasts a group of excellent engineers and enjoys a unique high-profile technology...

Ceramic Arm for Wafer Drive of Semiconductors

Touch-Down produced Ceramic arm for wafer drive of semiconductor feature good structural strength,...

Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut

Touch-Down (CNC precision machine grinding finished products) ensures the bolt size accuracy....

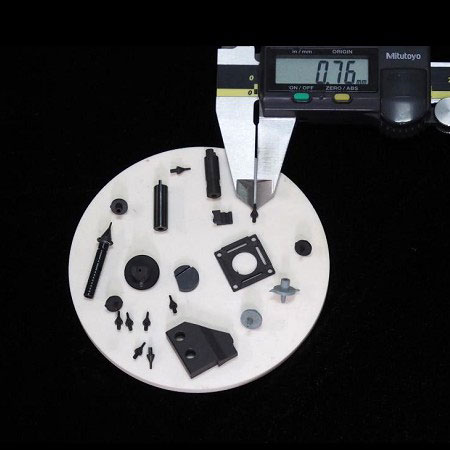

Precision Micro Ceramic Parts

More than 25 years of professional production and processing experience in alumina, zirconia,...

Porous Ceramic Chuck Table, Precise Porous Ceramic Partial Vacuum Chuck

High-density ceramic vacuum chuck (porous ceramic vacuum chuck) features the special porous...

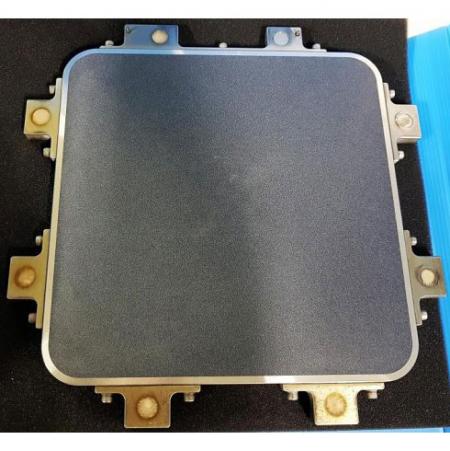

Combination of High-Precision Ceramic and Metal

It is a compact, high-precision ceramic part manufacturer, who is specialized in the manufacture...

Special-Shaped Precision Ceramic Parts

It is a compact, high-precision ceramic part manufacturer, who is specialized in the manufacture...

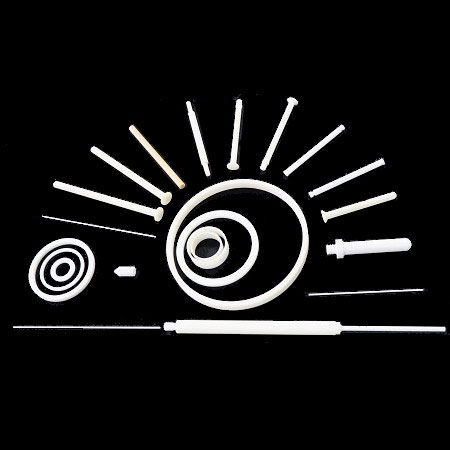

Precision Zirconia Ceramic Ring Gauge, Thread Gauge, Jig, Bolt, PIN

It is a compact, high-precision ceramic part manufacturer, who is specialized in the manufacture...

Grinding, Polishing and Processing of Ceramic Pole Tube

It is a compact, high-precision ceramic part manufacturer, who is specialized in the manufacture...

Precision Ceramic Parts for Household Use

It is a compact, high-precision ceramic part manufacturer, who is specialized in the manufacture...