Quartz (SiO₂) Applied to Ceramic Product

Quartz is a kind of glass like its name but what makes it different is that ordinary glass consists of many components, while quartz only consists of SiO₂. Because quartz contains very little amount of metallic impurities, only up to 10ppm (one hundred thousandth), the minimum state is usually only 10ppb (one over a billion) or less and because of its high purity, the quartz itself presents characteristics and advantages that other glass can not present.

Quartz (SiO₂) material features extremely low thermal expansion coefficient, high temperature resistance, high abrasion resistance, good chemical stability, electrical insulation, low and stable retardation, near ultraviolet (infrared) ray visible light transmittance, high mechanical properties and so on.

Therefore, high-purity quartz materials are widely used in modern electronic technology, semiconductor, telecommunications, electric light source, solar energy, national defense high-precision measuring instruments, laboratory physics and chemistry instruments, nuclear energy, nano-industries.

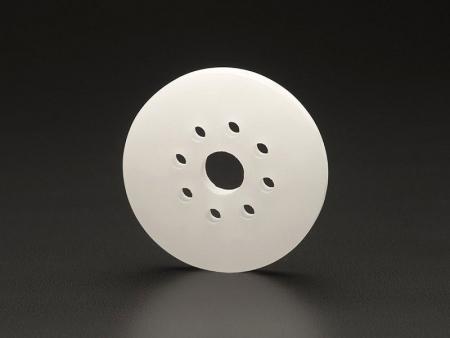

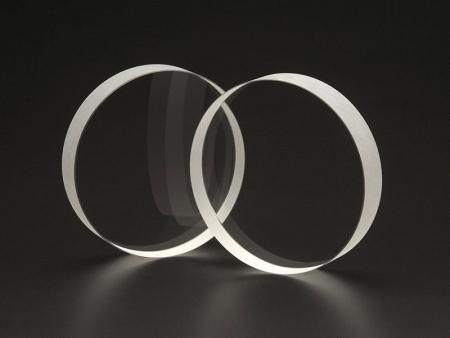

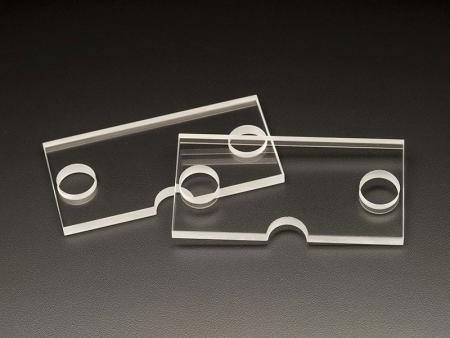

Semiconductor Applications

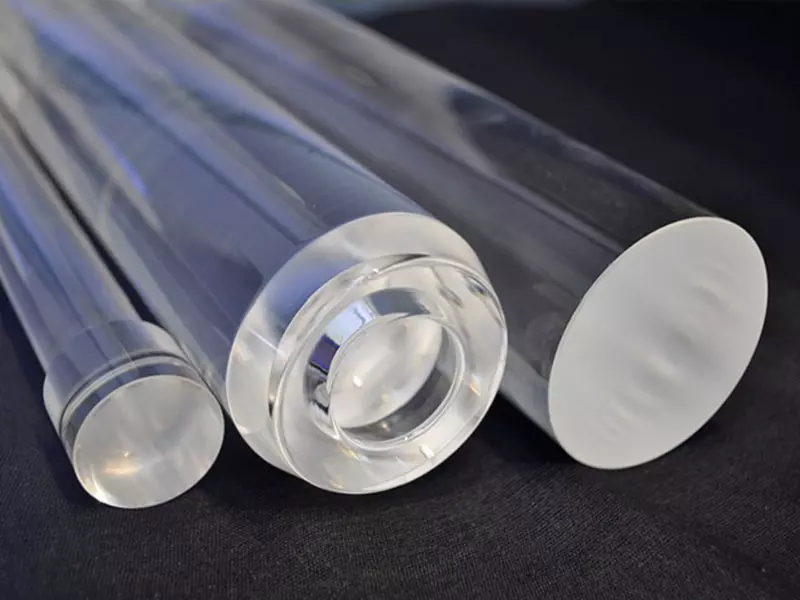

In the manufacturing process of semiconductor, the main quartz materials are used for quartz tube furnace, quartz boat, quartz ring, quartz tank, windows, process equipment and other related quartz components.

Quartz processing include: surface grinding, polishing, cylinder cutting, cutting, groove processing, curve processing, special-shaped processing, ultra-fine hole drilling, film coating.

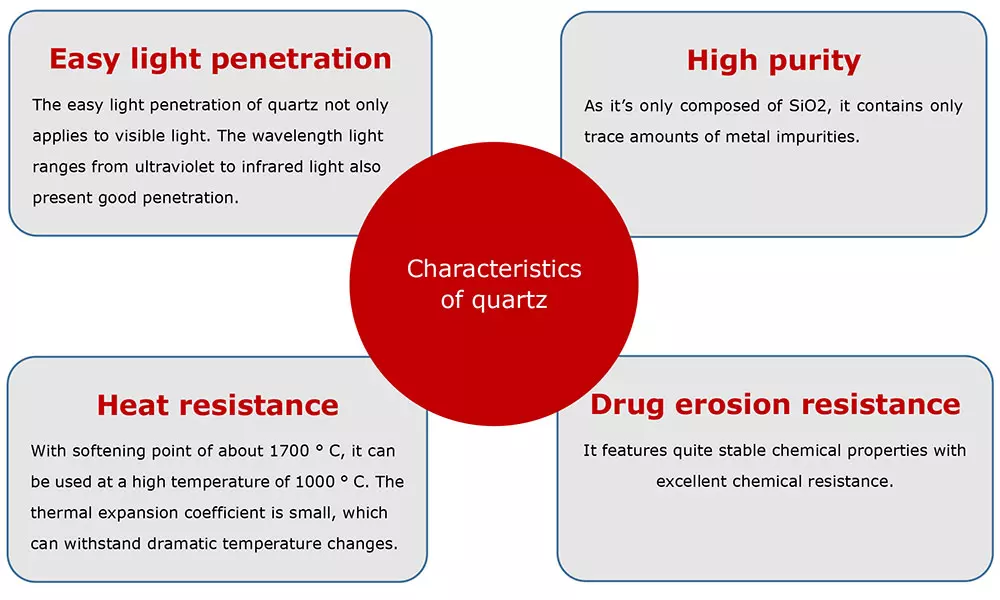

Characteristics Of Quartz

1. Easy Light Penetration

The easy light penetration of quartz not only applies to visible light. The wavelength light ranges from ultraviolet to infrared light also present good penetration.

2. High Purity

As it's only composed of SiO₂, it contains only trace amounts of metal impurities.

3. Heat Resistance

With softening point of about 1700°C, it can be used at a high temperature of 1000°C. The thermal expansion coefficient is small, which can withstand dramatic temperature changes.

4. Drug Erosion Resistance

It features quite stable chemical properties with excellent chemical resistance.

Quartz Material Characteristics Table

| Fe | Mg | Mn | K | Li | Co | Ni | Cu | Na | B | Ti | Ca | Al |

| 1.2 | 0.4 | 0.1 | 2.0 | 0.5 | < 0.02 | 0.03 | 0.57 | 2.3 | 0.8 | 0.1 | 0.8 | 16 |

| Category | 20°C | UV | IR | Visible light |

| Na value | 1.4586 ± 4 x 10-4 | 1.5341 - 1.4942 | 1.4251 - 1.47451 | 1.4698 - 1.45413 |

| Mean dispersion and dispersion coefficient / Nf-Nc=0.00674 ±3 x 10-4 / Dispersion coefficient Y= 680 | ||||

| Thermal Expansion Coefficient | Temperature °C | 100 | 300 | 500 | 700 | 900 | 1100 | ||

|---|---|---|---|---|---|---|---|---|---|

| Thermal Expansion Coefficient x 10-7 | 5.11 | 5.92 | 5.65 | 5.73 | 5.52 | 5.48 | |||

| Heat Conduction W/m°C | Temperature °C | 20 | 100 | 200 | 300 | 400 | 950 | ||

| Heat Conduction Coefficient | 1.38 | 1.47 | 1.55 | 1.67 | 1.84 | 2.68 | |||

| Thermal Energy Rate J/Kg°C | Temperature °C | 20 | 100 | 500 | 900 | ||||

| Thermal Energy Rate | 690 | 772 | 964 | 1052 | |||||

| Electricity Performance | Dielectric Constant (E) | 20°C | 23°C | 28°C | |

|---|---|---|---|---|---|

| 3.7 | 3.77 | 3.81 | |||

| (Tgδ) | 1 kHz | 1-1000 MHz | 3 x 10-4MHz | ||

| 0.0005 | 0.0001 | 0.0004 | |||

| Resistivity Factor (Ω cm) | 20°C | 400°C | 800°C | 1200°C | |

| 1016 | 1010 | 6.3 x 106 | 1.3 x 105 | ||

| AIO₃ | MgO | CaO | ZnO | Fe-Oxide | CuO | BaO | Basic-Oxide | PbO |

|---|---|---|---|---|---|---|---|---|

| > 1200°C | > 950°C | > 1000°C | > 800°C | > 950°C | > 950°C | > 900°C | > 800°C | Melting state |

| Density | 2.21 g/cm³ | Compression strength | 6000N/mm² 160000psi | Extension strength | 50 N/mm² | Torque force | 30 N/mm² |

|---|---|---|---|---|---|---|---|

| Mohs Hardness | 5.5 - 6.5 N/mm² | Torque coefficient | 3.1 x 104 N/mm² | Bending withstanding | 67 N/mm² | Sound velocity | 5720m x s |

Strain point: 1000 - 1125°C

Long-term use: below 1100°C

Annealing point: 1180°C

Short-term use: 1450°C

Softening point: 1600 - 1710°C

Melting: 1730°C