Characteristics and Application of Machinable Ceramics

Touch-down provides a variety of fine ceramics and machinable ceramics (also known as glass ceramics / mica ceramics). Our extensive material varieties may support large-scale application demands, including semiconductor processing equipment, integrated circuit testing as well as medical treatment diagnosis system.

These fine grains may be processed into ceramics, but shall not be processed with traditional tools, and the ceramics products are nearly as hard as aluminium oxide and other ceramics. Machinability and its high-strength fine-grain structure make these materials an ideal choice for precision processing and application.

Characteristics Of Machinable Glass Ceramic (Glass Ceramics)

The machinable glass ceramic is also known as glass ceramics, which is the mica glass ceramics with synthetic mica as main crystalline phase and is a kind of machinable ceramic material. The material is characterized by good machinable performance, vacuum performance, electric insulation, temperature insulation and resistance to chemical attack.

| Indicator | Standard Value | Description |

|---|---|---|

| Density | 2.7g/cm³ | |

| Apparent Porosity | 0.096% | |

| Water Absorption | 0.038 | |

| Hardness | 4 ~ 5 | Mohs |

| Color | Pure White | |

| Coefficient of Thermal Expansion | 86 x 10-7/°C | 100°C - 600°C on the average |

| Heat Conductivity | 1.68W/m.k | 25°C |

| Long-Term Operating Temperature | 800°C | |

| Bending Strength | 108Mpa | |

| Compression Strength | 488Mpa | |

| Impact Toughness | > 2.56KJ/m² | |

| Modulus of Elasticity | 65GPa | |

| Medium Loss | 1 ~ 4 x 10-3 | Room temperature |

| Dielectric Constant | 6 ~ 7 | Room temperature |

| Disruptive Strength | > 40KV/mm | 1mm Sample thickness of 1mm |

| Volume Resistance | 1.08 x 1014Ω.cm | 25°C |

| 1.5 x 1010 | 200°C | |

| 1.1 x 107 | 500°C | |

| Outgassing Rate at Room Temperature | 8.8 x 10-9 m1/s. cm² | Vacuum ageing for 8h |

| Helium Penetration Rate | 1 x 10-10m1/s | Cool to room temperature after firing at 500°C |

| 5%HC1 | 0.26mg/cm² | 95°C for 24h |

| 5%HF | 83mg/cm² | 95°C for 24h |

| 50%Na2CO3 | 0.012mg/cm² | 95°C for 24h |

| 5%NaOH | 0.85mg/cm² | 95°C for 24h |

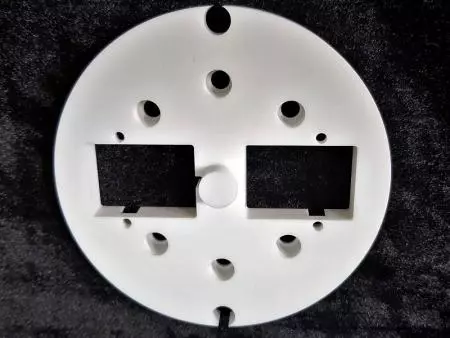

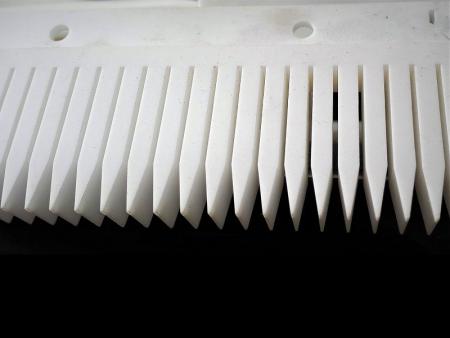

1. Machinability

The most prominent feature of glass ceramics is that it can be machined with standard metal processing tools and equipment in terms of turning, milling, digging, grinding, drilling, saw cutting and tapping. Generally speaking, it is not easy to machine aluminium oxide, silicon nitride ceramic and other insulating materials. The machinability of glass ceramics is similar to cast iron, which can be processed into complex, high-precision products in different shapes. Glass ceramics is fragile and hard, but it can be processed into high-precision finished products with attention paid to the processing method.

2. Electrical Performance

Glass ceramics is a kind of excellent high-temperature electrical insulating material, which can be used in many electrical equipment. In addition, it is characterized by higher electrical insulation strengthen, high volume resistance and low medium loss.

3. Thermal Performance

Glass ceramics is a kind of thigh-temperature endurable insulating material, and a kind of anti-corrosion electrical insulating material which can be widely used in ultralow temperature field. Its operating temperature is -270°C ~ +800°C. Since the mica crystal in glass ceramics has certain elasticity, it can prevent the extension of micro cracks, so it is also has a better thermal shock resistance. In addition, its low coefficient of thermal expansion ensures stable workpiece dimensions, so that air-tight seal can be achieved.

4. Other Performance

It is non-conductive magnet, specific gravity is 1/3 of common iron, even lighter than aluminum and water absorption is low.

Since it is fully composed of inorganic materials, it is also characterized by no ageing and deformation, very good stability to various organic solvents and good resistance to acid and alkali.

Because of its excellent comprehensive performance, microcrystalline glass ceramics can meet high-precision technical requirements, without mold design and production greatly shorten the development cycle, can accelerate the progress of the project, save the development costs. It is particularly suitable for being widely used in automobiles, military industry, aerospace, precise instruments, medical equipment, electric vacuum devices, electron beam exposure machine, textile machinery, sensors, mass spectrometer and spectrometer and other instruments. For some thin-walled coil skeleton, insulating supports of precise instruments and devices in complex shape and with higher requirements for precision, glass ceramics is more suitable because it can be processed into any shape. It has a higher strength and lower degassing rate than boron nitride and more heat-resisting than teflon. It is nondeformable, nonmetamorphic and durable, and has better machinability, shorter production cycle and higher pass rate than aluminum oxide ceramics, so that designers may manufacture the products in required size at will.

Application of Machinable Ceramics (Glass Ceramics / Mica Ceramics)

- Semiconductor equipment parts.

- Semi-conductor testing parts.

- Laser equipment parts.

- Vacuum equipment parts.

- Thin film deposition equipment parts.

- Linear motor parts.

- Various heat-insulated parts.

- 2D display processing equipment parts.

- Adhesive equipment parts.

- Positioning parts.

- Various sensor parts.

- Analysis equipment parts.

- Ultrasonic wave generator.

- Various insulated parts, etc.