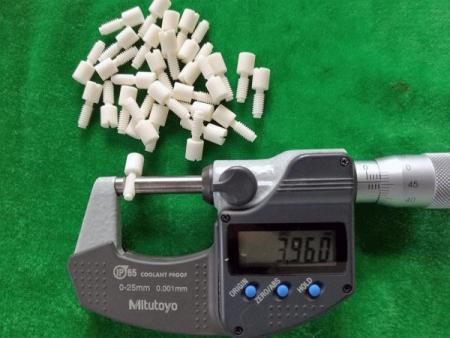

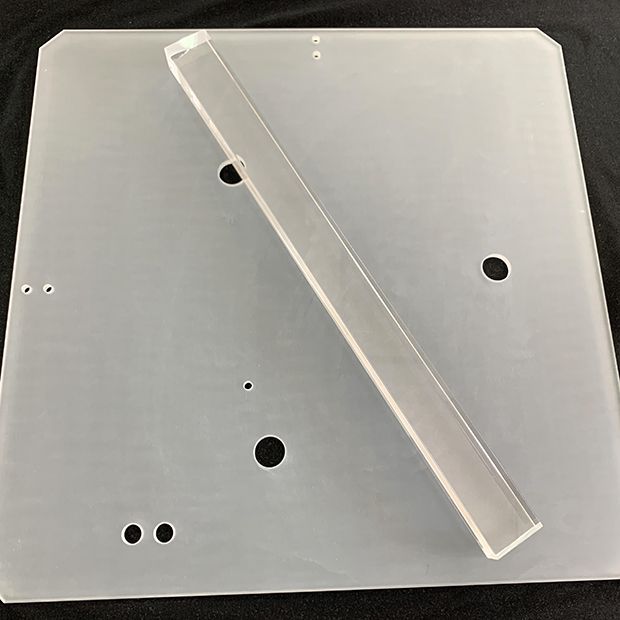

Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut

Touch-Down (CNC precision machine grinding finished products) ensures the bolt size accuracy. Touch-Down features a complete production line from raw materials - forming - sintering - flat grinding - external grinding - CNC program machine processing - polishing - cleaning packaging - shipping.

Located near the Science Park of Taiwan Hsinchu, the world-renowned science and technology town, our plant enjoys more than 25 years of professional production and processing experience in alumina, zirconia, silicon nitride, silicon carbide ceramic production and processing. We boast strong technical force, refined equipment and rich processing experience. Now we have several precision CNC equipment, precision machine tools, and a variety of leading processing technology and processing tools as well as sophisticated detection equipment to ensure product quality and precision. We are able to produce precision ceramic parts of a variety of specifications, types according to customer drawings. Our products feature high precision, good performance and are widely used in semiconductor, photovoltaic, precision machinery, military, medical, scientific research and other field.

Processing Object

Bolts and nuts for structural ceramics Semiconductor process equipment Implanter ceramic parts.

Type

Ceramic Bolt Parts (UNF / UNC Coarse and fine screw thread, Taper pipe threads).

Main Features

Touch-Down boasts a group of excellent engineers and enjoys a unique high-profile technology in the special-shaped ceramic processing projects. Special-shaped processing technology is the strengths of Touch-Down.

Touch-Down produced precision ceramic parts feature good structural strength, high temperature resistance, high pressure resistance, good accuracy, good parallelism, high density and uniform organization. For many years, it has been used by the semiconductor manufacturing plant.

Production Process

Touch-Down Features a Complete Production Line from Raw Materials - Forming - Sintering - Flat Grinding - External Grinding - CNC Program Machine Processing - Polishing - Cleaning Packaging - Shipping.

The Main Products

Ceramic Bolt, Ceramic Shaft, Zirconia Ceramic, Plug Gauge, Ring Gauge, Alumina Ceramic Arm, Ceramic Disc, Ceramic Ring, Microporous Ceramic Vacuum Chuck, Substrate, Ceramic, Ceramic Rails, Special-Shaped Pieces and so on.

- Gallery

- Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut, Production and Processing

- Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut, Production and Processing

- Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut, Production and Processing

- Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut, Production and Processing

- Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut, Production and Processing

- Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut, Production and Processing

- Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut, Production and Processing

- Files Download

Precision Ceramics

Touch-Down - Most accurate and professional long-term partner. Welcome to trial and proofing.

Download

Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut | Over 30 Years Advanced Ceramic Parts & Components Manufacturer | Touch-Down Technology Co., Ltd

Based in Taiwan since 1997, Touch-Down has been a fine ceramic parts and components manufacturer. Their main ceremic products, including Precision Ceramic, Aluminium Oxide, Zirconia, Screw Thread, Nut, fine ceramics, advanced ceramics and special ceramics integrating production, which are ISO 9001 certified.

Touch-Down is a compact, high-precision ceramic part manufacturer, who is specialized in the manufacture of fine ceramics / advanced ceramics / special ceramics integrating production and sales from raw material preparation, molding, plane grinding, abrasive machining of inner and outer diameters to digital processing of NC drilling crew. Over the past two decades, it has provided products and services for parts manufacturing and processing of fine ceramics, aluminium oxide, zirconium oxide, quartz and silicon carbide in terms of semiconductor processing, LED processing, TFT / LCD processing, solar chip processing, machinery production, medical and pharmaceutical industry and national defense and military.

Touch-Down has been selling advanced ceramics to US, Europe and Australia for over two decades since 1997, both with advanced technology and 30 years of experience, Touch-Down ensures each customer's demands are met.