Inspection Equipment

The diversified measurement laboratory that passes the international quality certification of ISO 9001:2008 can accurately detect product components and equipment parts. The imaging laboratory uses a variety of measurement probes to measure the dimensions of fine ceramics parts. Our laboratory is equipped with Mitutoyo’s efficiency 3D measurement equipment, Keyence's handheld detection 3D gauge and many other measurement technologies.

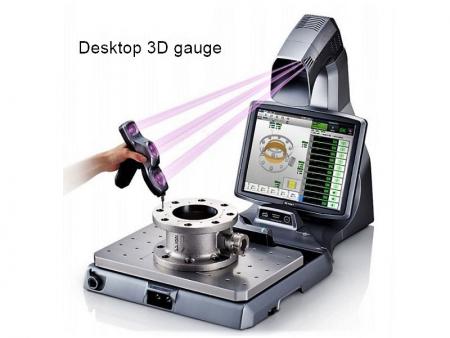

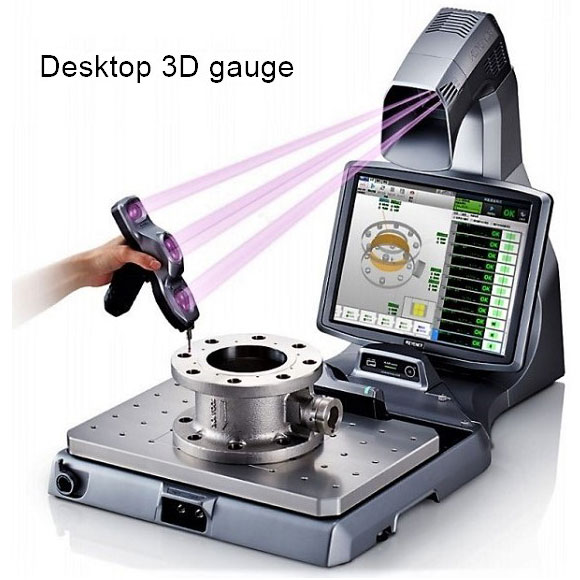

Touch-down continues to improve at the basic request of "customer first" and purchase the latest handheld 3D gauge to ensure that the quality can constantly be enhanced. In addition, it achieves the company's mission and improve the overall competitiveness based on customer satisfaction.

3D gauge uses the new principle, and CAMERA will be used to capture near-infrared light transmitted by 7 tag lights. Through the surface treatment at the nanometer level with about 100 LEDs, the repeated accuracy of ± 3μm may also be achieved even manually.

All equipment in laboratory has default program to eliminate human errors, which can be used to automatically and repeated execute the accurate measurement program throughout the process. Only good products can win customer trust. Therefore, we will not only carry out full quality inspection, but use the most advanced, accurate optical projector, height gage, plug gauge and a variety of electronic measurement equipment to exercise strict control over part quality. In addition, we will carefully carry out processing inspection in every stage of part processing and manufacturing, so that we can absolutely ensure the high precision quality of processed and manufactured parts with the commission of customers.

- a. Desktop 3D Gauge

- b. Desktop 3D Gauge

- c. Dimension Measurement Record Storage System

- d. 2.5D Manual Imaging Gauge

- e. Mitutoyo-Surface Roughness Gauge

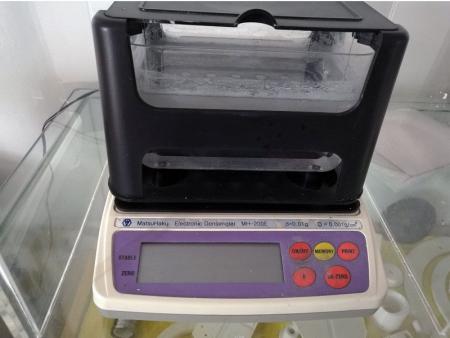

- f. Densimeter Gauge

- g. Mitutoyo-2.5D Automatic Imaging Gauge

- h. Standard Necessary Dimension Measurement and Correction Tool

h. Standard Necessary Dimension Measurement and Correction Tool: Mitutoyo's Micrometer, Vernier Caliper, Inner Diameter Gauge, Triangle Gauge and Height Gage.

Inner diameter ring gauges in line with Japan standard, with a variety of inner diameters 14 / 20 / 25 / 50 (zirconium oxide wear-resistant fine ceramics ring gauge).

Tolerance accuracy is within 0.0001 - 0.0003mm.